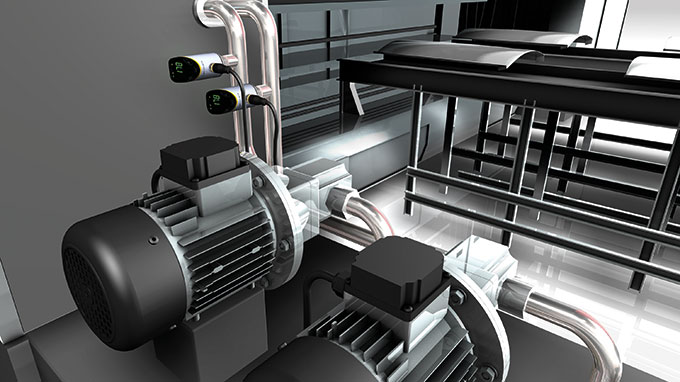

Controlling the hydraulic pressure in pressing plants

Piezoresistive pressure sensors assist users in carrying out predictive maintenance on presses

Pressure sensors monitor the hydraulic pressure in presses, in which steel and aluminum sheets are drawn, bent and punched. If an overpressure occurs due to a forming defect, this is detected immediately and reported to the controller. The PS+ series of intuitively operable sensors not only features high overpressure resistance but can also withstand the vibrations in pressing plants. The absence of mechanical operating elements enable protection classes IP6K6K, IP6K7 and IP6K9K.

Your Benefits

- Process analysis using the stored minimum/maximum pressure values helps to reduce downtimes

- Flexible mounting thanks to freely rotatable display and overhead installation

- Optimum adaptation to complex applications through hysteresis and filter functions

Condition Monitoring via IO-Link

Another feature also helps to prevent machine downtimes: Users can read out minimum and maximum pressures via IO-Link, identify any irregularities and proactively deal with the issue. This function is similar to a digital “drag pointer with long-term storage" and helps users with continuous condition monitoring of machines.

- Automobile

- Contrôle des Moteurs avec Condition Monitoring

- Module hybride IP67 Processus de traitement des signaux de sécurité

- Surveillance décentralisée des stations de refroidissement

- Cellules de soudage robotisées mises en réseau par Ethernet

- Surveillance du circuit de refroidissement des pinces à souder

- Contrôle du débit dans les laveurs de tambours

- Mesure d'épaisseur de tôle

- Condition Monitoring des moteurs

- Contrôle de niveau basé sur le cloud

- Atelier de presse – Identification d'outils

- Carrosserie – Détection des écrous à souder

- Atelier de peinture – Identification de skids

- Montage final – Montage robotisé

- Équipementiers – Système d'identification de pare-chocs

- Mécanique – Vérification sans contact

- Détection des corps dans la production automobile

- Protection de zone pour les cellules robotisées

- Détection au niveau des articles avec la RFID UHF

- Fourniture de réfrigérant lubrifiant dans les machines-outils

- Controlling hydraulic pressure in pressing plants

- Measuring process pressure on scissor lifts

- Inspection des becs sur des robots de soudure

- Chargement manuel dans une cellule de soudage

- Détection de pièces noires sur des panneaux de porte noirs

- Détection de verre transparent sur un toit vitré

- Inspection à longue portée dans le secteur de l'assemblage automobile

- Détection de rondelles de caoutchouc sur un bloc moteur

- Détection du positionnement des pièces dans un bloc moteur

- Détection de véhicules électriques aux bornes de recharge

- Détection de voitures dans un car-wash en libre-service

- SUCCESS STORIES

- Un capteur laser détecte les pare-chocs noirs dans une cellule d'assemblage

- Technologie de sécurité décentralisée pour une production modulaire

- Système de transport modulaire

- RFID and I/O Modules for Safe Tool Changes

- La technologie RFID pour guider un chariot autoguidé dans la production de suspensions

- IO-Link Wired Silencer Production

- Workpiece Carrier Identification in Rear Vent Production

- Détection d'écrous à souder

- Traçabilité RFID

- Technologie RFID dans la production de moteurs

- Production de pare-chocs avec système d'identification

- Solutions pour ateliers de peinture

- Capteurs de soudage et d'assemblage

- Capteurs d'angle pour systèmes d'assemblage

- Identification d'outils

- Système d'aide au choix pour la production de modules de pilotage

- Identification RFID des buses d'injection

- RFID in the Body Shop

- Ply Orientation Inspection

- IO-Link Eases Differential Gear Production

- Chimie

- Ethernet Signal Connection in the I&C Room

- Ethernet-based Automation of Modular Skids

- Ex Isolation in Modular Process Plants

- Détection d'écouvillons

- Systèmes d'E/S déportés pour le traitement de signaux

- Télésurveillance des niveaux de cuves avec le DX70

- Connexion aisée des équipements de terrain

- Traitement des signaux avec un système d'E/S dans l'armoire de commande

- Séparation des signaux avec une technologie d'interface dans une armoire de commande

- Identification de raccords de tuyaux

- Surveillance efficace d'armoires sur le terrain

- Surveillance d'actionneurs quart de tour

- Planification et assemblage de solutions système

- Success Stories

- Gain d'espace dans les salles I&C grâce au système d'E/S excom

- Technologie RFID pour les zones 2 et 22

- Contrôle de test efficace

- Communications de terrain intrinsèquement sûres

- Développement d'un système de contrôle des processus en partenariat

- Système d'E/S déporté pour zones dangereuses

- Double retour d'information sur la position des vannes

- La flexibilité offerte par un bus de terrain

- Asset Management with Remote I/O

- Positionnement correct avec la technologie RFID dans la production de carbure

- Fast conversion in restricted space

- Energie

- Agro-alimentaire

- Condition Monitoring of Control Cabinets

- Contrôle de la hauteur de la pâte pour une mesure précise

- Condition Monitoring in Storage Rooms

- Contrôle de l'épaisseur de pâte dans des lamineuses

- Identification de conteneurs alimentaires

- Détection du bord avant d'une barquette en plastique

- Détection de la position d'une vanne

- Vérification de récipients

- Vérification de l'exactitude de la date et du code de lot

- Détection de coudes de tuyaux

- Identification de moules à pralines

- Détection de petits pains réfrigérés sur un convoyeur multivoie

- Lecture de codes à barres dans un poste de dépalettisation

- Success Stories

- Détection de position linéaire fiable en zone Ex 22

- Modules de contrôle décentralisés dans les entrepôts frigorifiques

- Track and Trace in Meat Production with RFID

- Codeur sans contact pour la production de pommes de terre

- UHF RFID in Food Distribution Center

- La technologie RFID pour la production de pralines

- E/S distribuées pour l'équipement de production alimentaire

- Remote I/O for Distilleries

- RFID et autoclaves

- IP67 Power Supplies for Conveyors

- Transparency in Chocolate Manufacturing

- Identification dans l'entreposage de produits alimentaires

- Vérification fiable de l'orientation des bouchons dans des espaces aseptisés

- Détection de bouteilles transparentes renversées sur un dépalettiseur

- Détection de bouteilles en plastique transparent

- Inspection d'étiquettes d'emballages alimentaires surgelés

- Accumulation de bouteilles en file indienne sur une aligneuse simple

- Logistics

- Muting décentralisé des équipements de protection électro-sensible

- Container Check

- I/O Blocks Control Roller Conveyor Modules

- Détection rapide des étiquettes aux portes des entrepôts

- Item-level Detection with UHF RFID

- Preventive Maintenance on Conveyor Belts

- Detection of Transport Containers

- Level Detection in Vessels

- Identification of Cryovessels

- Identification of Mobile Containers with Handheld Devices

- Identification of Food Containers

- Tier 1 – Bumper Identification

- Surveillance de l'état des locaux de stockage

- Collision Protection on Reach Stackers

- Success Stories

- Solution RFID UHF décentralisée

- Contact-free Encoder in Potato Production

- Decentralized Control Modules in Coldstore

- Speed Control via Radar Sensor QT50

- IP67 Power Supplies for Conveyors

- Modular Conveyor System

- RFID Solution for Warehouse

- RFID Guides AGV in Suspension Production

- RFID Identifies Pharmaceuticals

- UHF RFID in Food Distribution Center

- Autonomous Parking Assistance for Trucks

- Equipement Mobile

- Surveillance de l'occupation d'un quai de chargement

- Automatic Slope Compensation

- Surveillance sans fil de roues de train

- Lignes de distribution pour pulvérisateurs agricoles

- Indication de l'état des reach stackers à l'aide de voyants lumineux intenses

- Mesure d'angle sur un pulvérisateur agricole

- Détermination du positionnement angulaire de la flèche

- Surveillance du sens de déplacement du matériau sur une moissonneuse-batteuse

- Véhicules dans une zone de chargement

- Éclairage de compartiments de rangement des équipements sur des véhicules de pompiers

- Signalisation sans fil pour chariot élévateur

- Mesure de l'inclinaison sur deux axes pour une moissonneuse-batteuse

- Protection contre la collision sur des reach stackers

- Success Stories

- Selective Asparagus Harvester

- Position Measurement with RFID and Encoder

- Contrôle de la vitesse avec le capteur radar QT50

- La technologie RFID pour guider un chariot autoguidé dans la production de suspensions

- Modules d'E/S sur un super yacht

- Codeur inusable sur une drague porteuse

- I/O for Dust Suppression

- Cabinet Cooling

- Connectique à raccord rapide

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Positionnement de hauteur exact

- Critical Angle Sensing

- Maintenance prédictive des pièces des machines dans une infrastructure de transport du charbon d'un port

- Angle Sensor Detects Platform Lift

- Pétrole et Gaz

- Emballage

- Decentralized RFID Package Verification

- Identification de cartouches d'impression couleur

- Fonctionnement fiable des machines

- Surveillance des bouchons sur des lignes de remplissage

- Surveillance des processus de changement de produits

- Identification de bouteilles de test

- Surveillance du niveau de remplissage de café moulu

- Détection de la notice d'information dans une boîte

- Détection du niveau de remplissage des récipients

- Calcul des dimensions des boîtes en carton

- Détection de bacs de transport

- Success Stories

- Détection de barquettes transparentes

- Vérification de la présence d'étiquettes correctes

- Détection de boîtes de différentes tailles sur un convoyeur

- Contrôle des codes à barres 2D à haute vitesse

- Détection d'emballages réfléchissants multicolores

- Mesure de diamètre d'un rouleau de film en plastique

- Positionnement de tubes à l'aide d'un repère

- Solutions pour ensacheuse verticale

- Pharma

- Suivi des échantillons du début à la fin grâce à la RFID

- RFID Control of Tube Connections in the Ex Area

- Decentralized package verification for pharmaceutical products

- Automate Modular Skids

- Comptage de comprimés à haute vitesse avec un amplificateur fibre

- Pharmaceutical Skids with Decentralized I/O Technology

- Ex Isolation in Modular Process Plants

- Détection de liquide dans des poches pour perfusion

- Control of Valve Interfaces

- Surveillance d'actionneurs quart de tour

- Détection de coudes de tuyaux

- Systèmes d'E/S déportés

- Planification et construction de superskids

- Surveillance de niveau de liquide dans une grande cuve

- Connexion aisée des équipements de terrain

- Identification de récipients cryogéniques

- Identification de contenants en mouvement

- Identification de contenants en mouvement à l'aide de terminaux portables

- Identification de raccords de tuyaux pour des précurseurs

- Identification de raccords de tuyaux dans des zones stériles

- Identification de raccords de tuyaux dans des zones explosives de classe 1

- Identification de big bags et de bioréacteurs

- Identification de produits à usage unique

- Semi-conducteur

- Electronic Marking Verification

- Counting Integrated Circuits

- Inspection of Two Barcodes

- Compact Safety Control

- Safeguarding Small Access Points

- Éclairage d'un outil de production dans le secteur des semi-conducteurs

- Adhesive Detection on PCB Assembly

- Détection du centre de plaques à l'aide du DF-G2

- Great Detail Inspection for Mobile Electronic Devices

- Error Proofing for IC Chips loaded into Pocket Tape

- Presence and Orientation of IC Chips Seated in Nests

- Detection of Hard Disks

- Multiproduct Light-Guided Assembly Station

- LED Status Indication During Semiconductor Manufacturing

- Safeguarding Small Access Points

- Success Stories

-turck-image.jpg)

-turck-image.jpg)

-turck-image.jpg)

-turck-thumbnail.jpg)

-turck-thumbnail.jpg)

-turck-thumbnail.jpg)