Monitoring of Paper Presses by I/O Solution

Packaging manufacturer DS Smith monitors its paper presses at its Erlensee plant with an intelligent I/O solution from Turck

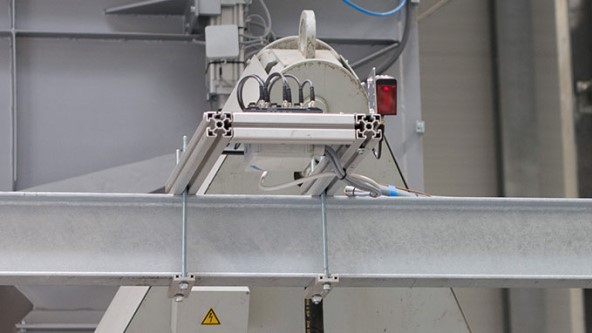

DS Smith is one of the leading manufacturers of customized packaging and displays using corrugated board as a base material. The company has up to now been monitoring manually the output of its paper presses in the Erlensee plant near Hanau. A complete solution now automatically provides employees with information from laser sensors and an intelligent I/O module about when the bales from the two paper presses have reached the maximum limit and have to be moved away. This saves a lot of time since employees no longer have to continually check progress in the neighboring hall. Turck’s TBEN-S compact I/O module with the ARGEE integrated field logic controller operates here as a stand-alone controller – directly in the field, without the need for a control cabinet.

DS Smith, one of the leading manufacturers of customized packaging and displays in Europe, is preparing its reject material for recycling at the factory. Offcuts and faulty packaging are shredded in a waste press, compressed into cubes and transferred into the storage room. So far, the only thing missing was a feedback signal from the press. It was always necessary for an employee to stop working and check the progress of the machine.

Basic light sensor not enough

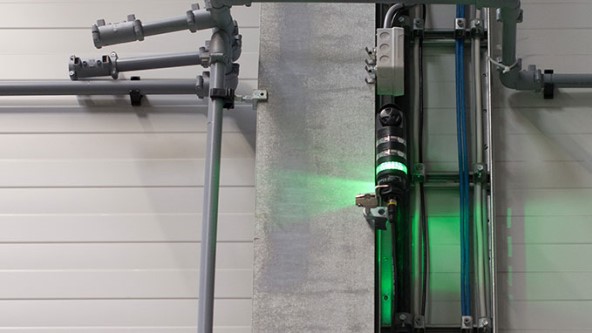

To prevent this, a system had to be used that would provide information on the progress of the bales. In order to ensure a correct switchoff, a sensor was needed that not only supplied switching information but also measured the distance, so that it would only switch within a specified switching distance window. However, passing colleagues and employees who are removing bales with a fork lift truck would also be detected by the sensor. Added to this is the fact that structural factors prevented the sensor from being mounted at the side since the wall required for this had a rolling door. Simple light sensors, light switches or a photoelectric sensor were therefore unsuitable for the requirements at DS Smith.

Decentralized intelligence without a control cabinet

Manfred Ernst, specialist automation consultant at Sonepar, recommended a measuring laser sensor, which, in combination with a compact controller, could evaluate the data and trigger an appropriate signal. Ernst had already got to know Turck’s I/O modules with the ARGEE integrated programming environment and tested it at the customer’s site.

When the LTF12 laser sensor with the connected TBEN-S was tested in the Erlensee plant, Freppon was greatly impressed: “At first I thought I needed a control cabinet as well as the sensor. However, we then came upon the TBEN-S module with ARGEE. This fitted perfectly straightaway. It is compact, fits everywhere and offers very good protection to IP67, thus eliminating the need for a control cabinet.”

Intuitive programming in an instant

The timer was programmed via ARGEE likewise as a condition. Freppon selected a factor here of 45 seconds. This time factor prevents error messages caused by people in the light beam or passing fork lift trucks. TL50 LED traffic light outside of the hall indicates the status of the machine at any time. This enables employees to carry out their work and only requires them to intervene when the signal is activated. These settings also offer additional safety.

- Automobile

- Mesure d'épaisseur de tôle

- Atelier de presse – Identification d'outils

- Carrosserie – Détection des écrous à souder

- Atelier de peinture – Identification de skids

- Montage final – Montage robotisé

- Montage final – Diagnostic de fuites

- Équipementiers – Système d'identification de pare-chocs

- Protection de zone pour les cellules robotisées

- Mécanique – Vérification sans contact

- Détection des corps dans la production automobile

- Inspection des becs sur des robots de soudure

- Supply of cooling lubricant in machine tools

- Controlling hydraulic pressure in pressing plants

- Measuring process pressure on scissor lifts

- Chargement manuel dans une cellule de soudage

- Détection de pièces noires sur des panneaux de porte noirs

- Détection de verre transparent sur un toit vitré

- Inspection à longue portée dans le secteur de l'assemblage automobile

- Détection de rondelles de caoutchouc sur un bloc moteur

- Détection du positionnement des pièces dans un bloc moteur

- Détection de véhicules électriques aux bornes de recharge

- Détection de voitures dans un car-wash en libre-service

- SUCCESS STORIES

- Modular Conveyor System

- RFID and I/O Modules for Safe Tool Changes

- RFID Guides AGV in Suspension Production

- IO-Link Wired Silencer Production

- Workpiece Carrier Identification in Rear Vent Production

- Weld Nut Sensing

- Traçabilité RFID

- RFID in Engine Production

- Production de pare-chocs avec système d'identification

- Solutions pour ateliers de peinture

- Welding and Assembly Sensors

- Capteurs d'angle pour systèmes d'assemblage

- Identification d'outils

- Système d'aide au choix pour la production de modules de pilotage

- Identification RFID des buses d'injection

- RFID in the Body Shop

- IO-Link Eases Differential Gear Production

- Ply Orientation Inspection

- Chimie

- Détection d'écouvillons

- Systèmes d'E/S déportés pour le traitement de signaux

- Connexion aisée des équipements de terrain

- Télésurveillance des niveaux de cuves avec le DX70

- Traitement des signaux avec un système d'E/S dans l'armoire de commande

- Séparation des signaux avec une technologie d'interface dans une armoire de commande

- Identification de raccords de tuyaux

- Surveillance efficace d'armoires sur le terrain

- Surveillance d'actionneurs quart de tour

- Planification et assemblage de solutions système

- Success Stories

- Gain d'espace dans les salles I&C grâce au système d'E/S excom

- Technologie RFID pour les zones 2 et 22

- Contrôle de test efficace

- Communications de terrain intrinsèquement sûres

- Développement d'un système de contrôle des processus en partenariat

- Système d'E/S déporté pour zones dangereuses

- Dual Valve Position Feedback

- Flexibility with Fieldbus

- Asset Management with Remote I/O

- Positionnement correct avec la technologie RFID dans la production de carbure

- Fast conversion in restricted space

- Energie

- Agro-alimentaire

- Contrôle de la hauteur de la pâte pour une mesure précise

- Contrôle de l'épaisseur de pâte dans des lamineuses

- Détection du bord avant d'une barquette en plastique

- Identification de conteneurs alimentaires

- Vérification de l'exactitude de la date et du code de lot

- Détection de la position d'une vanne

- Vérification de récipients

- Lecture de codes à barres dans un poste de dépalettisation

- Détection de coudes de tuyaux

- Vérification fiable de l'orientation des bouchons dans des espaces aseptisés

- Identification de moules à pralines

- Détection de bouteilles transparentes renversées sur un dépalettiseur

- Détection de bouteilles en plastique transparent

- Inspection d'étiquettes d'emballages alimentaires surgelés

- Accumulation de bouteilles en file indienne sur une aligneuse simple

- Détection de petits pains réfrigérés sur un convoyeur multivoie

- Success Stories

- Track and Trace in Meat Production with RFID

- Contact-free Encoder in Potato Production

- UHF RFID in Food Distribution Center

- RFID for Chocolate production

- E/S distribuées pour l'équipement de production alimentaire

- Remote I/O for Distilleries

- RFID et autoclaves

- IP67 Power Supplies for Conveyors

- Transparency in Chocolate Manufacturing

- Identification in Food Product Storage

- Equipement Mobile

- Surveillance de l'occupation d'un quai de chargement

- Surveillance sans fil de roues de train

- Lignes de distribution pour pulvérisateurs agricoles

- Indication de l'état des reach stackers à l'aide de voyants lumineux intenses

- Mesure d'angle sur un pulvérisateur agricole

- Détermination du positionnement angulaire de la flèche

- Surveillance du sens de déplacement du matériau sur une moissonneuse-batteuse

- Véhicules dans une zone de chargement

- Éclairage de compartiments de rangement des équipements sur des véhicules de pompiers

- Signalisation sans fil pour chariot élévateur

- Mesure de l'inclinaison sur deux axes pour une moissonneuse-batteuse

- Protection contre la collision sur des reach stackers

- Success Stories

- Position Measurement with RFID and Encoder

- Speed Control via Radar Sensor QT50

- La technologie RFID pour guider un chariot autoguidé dans la production de suspensions

- Modules d'E/S sur un super yacht

- Wear-free Encoder on Hopper Dredger

- I/O for Dust Suppression

- Cabinet Cooling

- Quick Disconnect Connectivity

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Exact Height Positioning

- Critical Angle Sensing

- Angle Sensor Detects Platform Lift

- Maintenance prédictive des pièces des machines dans une infrastructure de transport du charbon d'un port

- Pétrole et Gaz

- Emballage

- Identification de cartouches d'impression couleur

- Fonctionnement fiable des machines

- Surveillance des bouchons sur des lignes de remplissage

- Surveillance des processus de changement de produits

- Identification de bouteilles de test

- Surveillance du niveau de remplissage de café moulu

- Détection de la notice d'information dans une boîte

- Détection du niveau de remplissage des récipients

- Calcul des dimensions des boîtes en carton

- Détection de bacs de transport

- Détection de barquettes transparentes

- Vérification de la présence d'étiquettes correctes

- Détection de boîtes de différentes tailles sur un convoyeur

- Contrôle des codes à barres 2D à haute vitesse

- Détection d'emballages réfléchissants multicolores

- Mesure de diamètre d'un rouleau de film en plastique

- Positionnement de tubes à l'aide d'un repère

- Solutions pour ensacheuse verticale

- Success Stories

- Pharma

- Comptage de comprimés à haute vitesse avec un amplificateur fibre

- Surveillance d'actionneurs quart de tour

- Détection de coudes de tuyaux

- Systèmes d'E/S déportés

- Planification et construction de superskids

- Détection de liquide dans des poches pour perfusion

- Connexion aisée des équipements de terrain

- Identification de récipients cryogéniques

- Surveillance de niveau de liquide dans une grande cuve

- Identification de contenants en mouvement

- Identification de contenants en mouvement à l'aide de terminaux portables

- Identification de raccords de tuyaux pour des précurseurs

- Identification de raccords de tuyaux dans des zones stériles

- Identification de raccords de tuyaux dans des zones explosives de classe 1

- Identification de big bags et de bioréacteurs

- Identification de produits à usage unique

- Semi-conducteur

- Adhesive Detection on PCB Assembly

- Éclairage d'un outil de production dans le secteur des semi-conducteurs

- Détection du centre de plaques à l'aide du DF-G2

- Great Detail Inspection for Mobile Electronic Devices

- Error Proofing for IC Chips loaded into Pocket Tape

- Presence and Orientation of IC Chips Seated in Nests

- Detection of Hard Disks

- Multiproduct Light-Guided Assembly Station

- Success Stories