RFID in Zones 2 and 22

At its Burghausen site, WACKER is using Turck's BL ident RFID system for reliable detection in its tumbler screening systems in the dust Ex zone 22

Depending on the application, dispersion powder must be manufactured in different grain sizes. To ensure and document this process, WACKER in Burghausen has for the past year been identifying the mesh width of its tumbler screens with Turck's BL ident RFID system, which is also approved for use in dust hazardous areas. As a result of its good experience with this system, the company is also now equipping the first coupling stations with it.

The most important production site for, idyllically situated on the Austrian border, in the so-called ‘Bavarian chemical triangle’. The chemical plant, covering a two kilometer area, employs 10,000 people in around 150 facilities, and produces thousands of different products.

In Burghausen the chemical company WACKER produces dispersion powders that are added to tile adhesives, plaster, screeds and other building materials so that they are given particular properties. To produce the end product, a liquid is dried in a drying tower at the end of the production process. The resulting powder then has to be vibrated through a screen before it can then be packaged. This ensures that the product concerned has the required grain size.

In order to increase transparency and traceability in the production of dispersion powder, the production plant expressed the wish for the automatic detection of the screen size used in the tumbler screens. “The correct screen size was previously measured manually by colleagues in the plant,” Michael Holzapfel, plant engineer responsible for electrical engineering in the Construction Polymers division, explains. “In order to exclude the possibility of human error, the screen used for each batch now has to be measured automatically. This enables us to not only guarantee the 100% quality of the ongoing process, but also to have a retrospective record of the correct screening process.”

Due to the particular environmental conditions at Burghausen, WACKER gradually came to the idea of using an RFID solution. The solution nevertheless had to be approved for use in the dust Ex zone. “Turck was the only manufacturer that could offer us an RFID system that is Ex-approved for zone 22 dust,” Holzapfel describes the original reason for choosing the system of the Mülheim automation specialist.

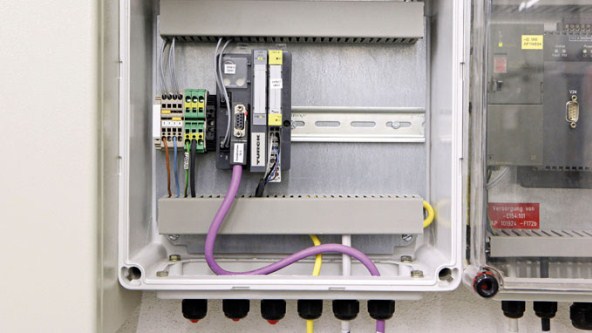

Up to now WACKER has fitted four tumbler screens with a type TNLR-Q80-H1147-Ex read/write head that is approved for use in Ex zones 2 and 22. All the screens used there were fitted with a TW-R50-B128-Ex tag on which the mesh width is stored. The disk-shaped tag is fitted at the edge of the screen, directly under a strap with the optical marking of the mesh width. The read/ write head reads the mesh width and passes on the data to the process control system via Profibus using one of three BL20 I/O stations.

During the course of the installation yet one other hurdle had to be overcome: “The function block supplied with the RFID system is programmed for a Siemens S7 PLC and not for a Siemens PCS7 process control system like we use here,” Holzapfel explains. “However, our software specialists worked in close collaboration with Turck Support to quickly adapt the S7 function block so that it can now also run on the PCS7.”

- Automobile

- Press Shop – Tool Identification

- Sheet Metal Thickness Measurement

- Body Shop – Welding Nut Detection

- Paint Shop – Skid Identification

- Area Guarding for Robotic Cells

- Final Assembly – Robot Assembly

- Inspection of Tips on a Welder

- Final Assembly – Diagnosis of Leaks

- Tier 1 – Bumper Identification

- Manual Feeding in Weld Cell

- Powertrain – Contactless Verification

- Body Detection in Automobile Production

- Detecting Black Parts on Black Door Panel

- Moonroof Clear Glass Detection

- Long-Range Inspection in Automotive Assembly

- Rubber Washer Detection on Engine Block

- Engine Block Part-In-Place Detection

- Electric Vehicle Detection in Charging Station

- Vehicle Detection in a Self-Serve Car Wash

- SUCCESS STORIES

- RFID Guides AGV in Suspension Production

- IO-Link Wired Silencer Production

- Workpiece Carrier Identification in Rear Vent Production

- Weld Nut Sensing

- RFID Traceability

- RFID in Engine Production

- Bumper Production with Identification

- Solutions for Paint Shops

- Welding and Assembly Sensors

- Angle Sensors for Assembly Systems

- Tool Identification

- RFID Identification of Injector Nozzles

- RFID in the Body Shop

- IO-Link Eases Differential Gear Production

- Pick-to-Light for Bumper Assembly

- RFID and I/O Modules for Safe Tool Changes

- Ply Orientation Inspection

- Chimie

- Detection of Pigs

- Remote Signal I/O

- Easy Connection of Field Devices

- Remote Tank Level Monitoring with DX70

- Signal Processing with System I/O in the Control Cabinet

- Signal Separation with Interface Technology in the Control Cabinet

- Identification of Hose Connections

- Efficient Monitoring of Cabinets in the Field

- Monitoring of Quarter Turn Actuators

- Planning and Assembly of System Solutions

- Success Stories

- I/O System Excom Creates Space in the I&C Rooms

- Zone 2 and 22 RFID

- Efficient Testing Control

- Intrinsically Safe Field Communication

- Process Control System Partnership

- Hazardous Area Remote I/O

- Dual Valve Position Feedback

- Flexibility with Fieldbus

- Asset Management with Remote I/O

- Correct Positioning with RFID in Carbide Production

- Energie

- Agro-alimentaire

- Dough Height Inspection for Accurate Measurement

- Dough Thickness Control in Rolling Machines

- Leading Edge Detection of Plastic Container

- Identification of Food Containers

- Date/Lot Code Verification

- Container Check

- Detection of Valve Position

- Barcode Reading on Depalletizer Station

- Reliable Cap Orientation Verification in Aseptic Areas

- Detection of Pipe Elbows

- Clear and Tipped Bottle Detection on Depalletizer

- Clear Plastic Bottle Detection

- Identification of Chocolate Moulds

- Frozen Food Packaging Label Inspection

- In-Line Bottle Accumulation on Single Filer

- Detecting Refrigerated Breakfast Rolls on a Multi-Lane Conveyor

- Success Stories

- Track and Trace in Meat Production with RFID

- Contact-free Encoder in Potato Production

- UHF RFID in Food Distribution Center

- RFID for Chocolate production

- Distributed I/O for Food Equipment

- Remote I/O for Distilleries

- RFID and Autoclaves

- IP67 Power Supplies for Conveyors

- Transparency in Chocolate Manufacturing

- Identification in Food Product Storage

- Equipement Mobile

- Distribution Lines for Field Sprayers

- Loading Dock Occupancy Monitoring

- Measuring the Ground Clearance on a Field Sprayer

- Monitoring Railcars Wheels Wirelessly

- Reach Stacker Status With Bright Lighting Indicators

- Angle Measurement on a Field Sprayer

- Determining the Boom Angle Position

- Material Flow Monitoring on a Combine Harvester

- Vehicle at Loading Dock

- Equipment Compartment Illumination on Fire Engines

- Wireless Forklift Signaling

- Two-Axis Tilt Measurement on a Combine Harvester

- Success Stories

- Position Measurement with RFID and Encoder

- Speed Control via Radar Sensor QT50

- RFID Guides AGV in Suspension Production

- Block I/O Modules on Super Yacht

- Wear-free Encoder on Hopper Dredger

- I/O for Dust Suppression

- Cabinet Cooling

- Quick Disconnect Connectivity

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Exact Height Positioning

- Critical Angle Sensing

- Angle Sensor Detects Platform Lift

- Predictive Maintenance of Machine Parts at Port-Based Coal Conveying Facility

- Pétrole et Gaz

- Emballage

- Identification of Printing Color Cartridges

- Reliable Operation of Machines

- Monitoring of Caps in Filling Lines

- Monitoring Changeover Processes

- Identification of Test Bottles

- Level Monitoring of Ground Coffee

- Box Insert Detection

- Carton Dimensioning

- Clear Container Detection

- Correct Label Verification

- Detecting Different Size Packages on a Conveyor

- High-Speed 2D Barcode Inspection

- Multicolored Reflective Package Detection

- Plastic Roll Diameter Measurement

- Tube Positioning Using a Registration Mark

- Vertical Form Fill Seal Machine Solutions

- Success Stories

- Pharma

- Monitoring of Quarter Turn Actuators

- Detection of Pipe Elbows

- High-Speed Tablet Counting With Fiber Amplifier

- Remote Signal I/O

- Planning and Construction of Super Skids

- I.V. Bag Liquid Detection

- Easy Connection of Field Devices

- Identification of Portable Tanks

- Identification of Cryovessels

- Identification of Mobile Containers

- Liquid Level Monitoring In A Large Tank

- Identification of Mobile Containers with Handheld Devices

- Identification of Hose Connections for Precursors

- Identification of Hose Connections in Sterile Areas

- Identification of Hose Connections in Ex Zone 1

- Identification of Big Bags and Bioreactors

- Identification of Single-Use Applications

- Semi-conducteur